Capabilities

In August of 2017 due to continued growth, JBT Machining moved into a 42,000 square foot fully air conditioned manufacturing facility.

- 42,000 sq. ft. facility

- 20,000 sq. ft. available for expansion

- LED Lighting

- Badge Access Entry & 24/7 Video Monitoring

- Loading Docks

- All 42,000 sq. ft. it environmentally controlled

JBT has done many Assembly projects. Our current facility has future expansion capabilities of 20,000 square feet for additional growth. The assembly process starts with JBT manufacturing the machined parts and then assembling them with the purchased components (ball screws, linear rails, bearing assembly’s, gear reduction transmissions, electric motors etc.) the end result gives our customer the ability to stream line their production process.

JBT has done many Assembly projects. Our current facility has future expansion capabilities of 20,000 square feet for additional growth. The assembly process starts with JBT manufacturing the machined parts and then assembling them with the purchased components (ball screws, linear rails, bearing assembly’s, gear reduction transmissions, electric motors etc.) the end result gives our customer the ability to stream line their production process.

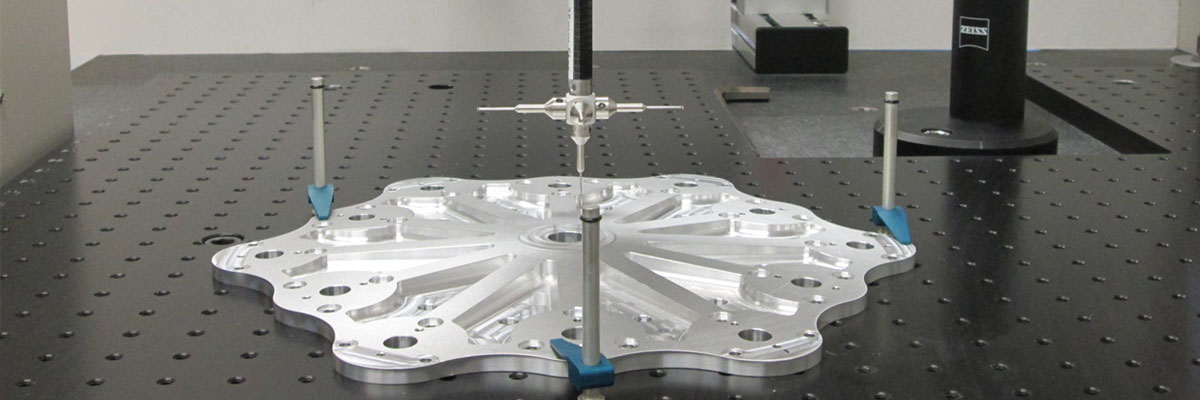

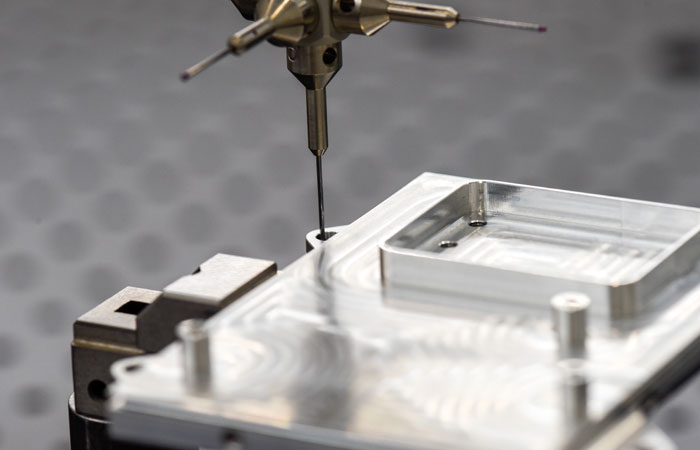

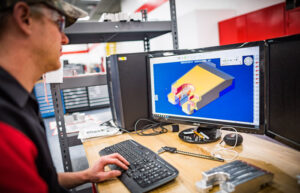

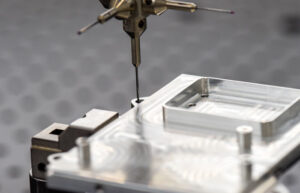

JBT Engineering and Quality personal work with Gibbs Cam Complete, MasterCAM and Calypso Cad based CMM software to create automated machining and inspection processes.

JBT has a large variety of CNC Mills with up to 5 axis positioning and a 28-pallet changer system capable of lights out production. Our Milling departments capacity is up to 166in on the X-axis and 86in on the Y-axis and has a proven success record with both low and high-volume prototype / production jobs.

JBT’s turning department has twin turret, twin spindle live equipment capable of handling simultaneous operations that can efficiently cover all your prototype to Production turning needs up to 10 inch in diameter and 20in in length

Prototyping to Production, JBT’s high precision machine shop has the equipment and staff to efficiently handle all of your manufacturing projects big or small.

JBT’s sawing department is capable of sawing material up to 16 inches in diameter and up to 30 feet in length. With large ceiling cranes, handling this heavy material is very easy for JBT.

JBT’s sawing department is capable of sawing material up to 16 inches in diameter and up to 30 feet in length. With large ceiling cranes, handling this heavy material is very easy for JBT.

JBT is very efficient in doing short run quantities. We have been doing this successfully for since 1994 and have the correct equipment and staff to meet your needs.